Every customers need is different. Therefore our partners don’t get any standard offers but individual services that fit precisely to the specific situation and tasks.

At IC-e, this strong customer orientation applies to all service areas - from project planning, software development and visualization to production and commissioning.

Our services for your machines and plants of safety engineering:

- risk analyses and hazard assessments

- functional safety of machines

- implementation of safety functions

- validations

- documentation according to the Machinery Directive 2006/42/EC

- CE documentation

Automation

Automation

No two eggs are alike. – And the same applies to the wishes of our customers, which we take to heart. This is why comprehensive, detailed and concrete analyses always form the basis for the best possible automation solution. The focus is on the process.

After the analysis, the planning process begins quickly: Important components are tasks in the area of SPS (programmable memory controller), in safety technology and drive technology as well as visualization of different manufacturers.

A further advantage in the cooperation with IC-e: In addition to our core competencies, we also offer other modules for the successful completion of a plant project. This can include mechanical assemblies as well as electrical installations, which we implement together with our network of permanent partners. The concrete design is then based on the concrete challenge. The aim is to provide the client with a turnkey solution.

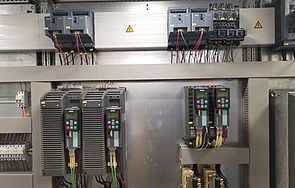

Drive Engineering

Drive Engineering

Our employees have many years of experience and a great deal of specialist knowledge in drive control. This includes the operation and use of frequency converters, soft starters, servo technology and power converters from Siemens, Danfoss, SEW, ABB and others.

Application examples:

- rotary hearth, tempering and hardening furnace

- roller tables

- quick transports

- portals with up to 3 servo axes

- pipe marking systems

- socket screwdriver

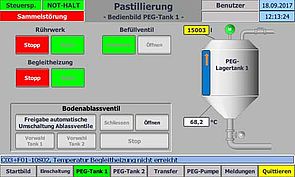

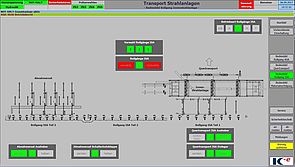

Visualisation

Visualisation

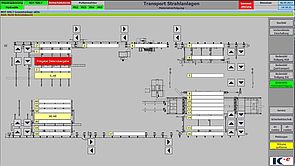

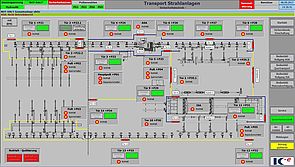

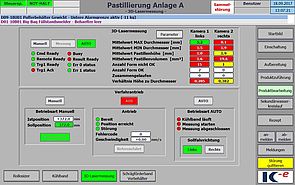

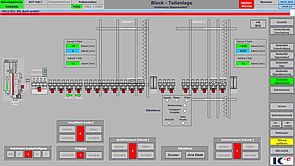

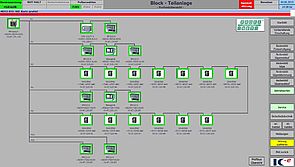

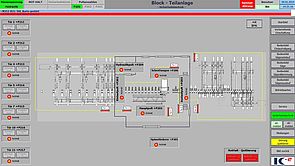

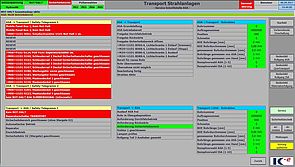

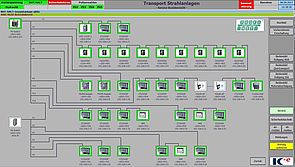

In times of "Industry 4.0", the abbreviation "HMI" is also ubiquitous. What the "Human Machine Interface" means, however, and what requirements and, above all, possibilities are hidden behind it, can be experienced at IC-e. Because visualizations created with WinCC and/or Intouch are created according to customer requirements and provide the best possible transparency and user-friendliness.

The art here is to present the complex in a clear and easily comprehensible way, so that the operator intuitively makes the right decisions and makes the right settings.

This in turn benefits the process. Smooth production processes improve the operating result.

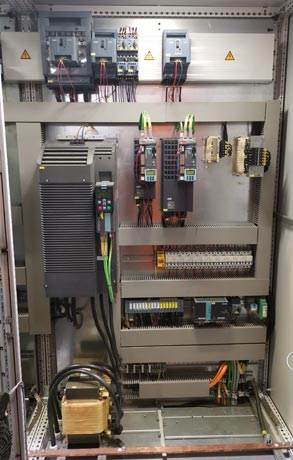

Switchgear Engineering

Switchgear Engineering

We plan and construct switchgear with Eplan.

Individually, after a detailed analysis of the customer requirements, we create the hardware design and manufacture in our own workshop, taking into account the current standards and regulations. The quality is also in the detail here: in the arrangement of the components, in the materials used, in the many small parts of the lettering.

We attach the greatest importance to quality in the manufacture of switch cabinets. We work quickly and reliably with state-of-the-art technology.

After completion, double quality control takes place: the workshop test and the respective functional tests are followed by acceptance and commissioning at the customer's premises.

Machine and Plant Construction

Machine and Plant Construction

Together with our network of permanent partners, we create turnkey plants according to customer requirements. Here we take over the construction – mechanical as well as electrical – as well as the production and commissioning.

We assemble the plants completely in our own workshops. Our first own test runs are followed by the "Factory Acceptance Test" (FAT) in the presence of the customer, either live on site or via video switch.

Thanks to the close cooperation and well-rehearsed teams in our partner network, interfaces are eliminated and smooth coordination is achieved. At the end of the day, the customer benefits from this as well: the result is better, available faster, and thus more cost-effective.